Did you ever hear this proverb?

For want of a nail the shoe was lost.

For want of a shoe the horse was lost.

For want of a horse the rider was lost.

For want of a rider the battle was lost.

For want of a battle the kingdom was lost.

And all for the want of a horseshoe nail.

The parable is unreasonably apt to business transformation projects. A single missing status can cause the entire initiative to fail.

What Causes Failure in Projects?

Before I share my anecdote, let’s talk about failure for a minute. We’ve all experienced it at some point, and on transformative projects, more often than not it’s not one gigantic collapse caused by one huge error that does you in. Rather, it’s usually death by a thousand papercuts. An accretion of little failures that add up to the bigger no-go.

The key to avoiding failure is seeing those papercuts as they happen and course-correcting as soon as possible to cauterize the bleeding.

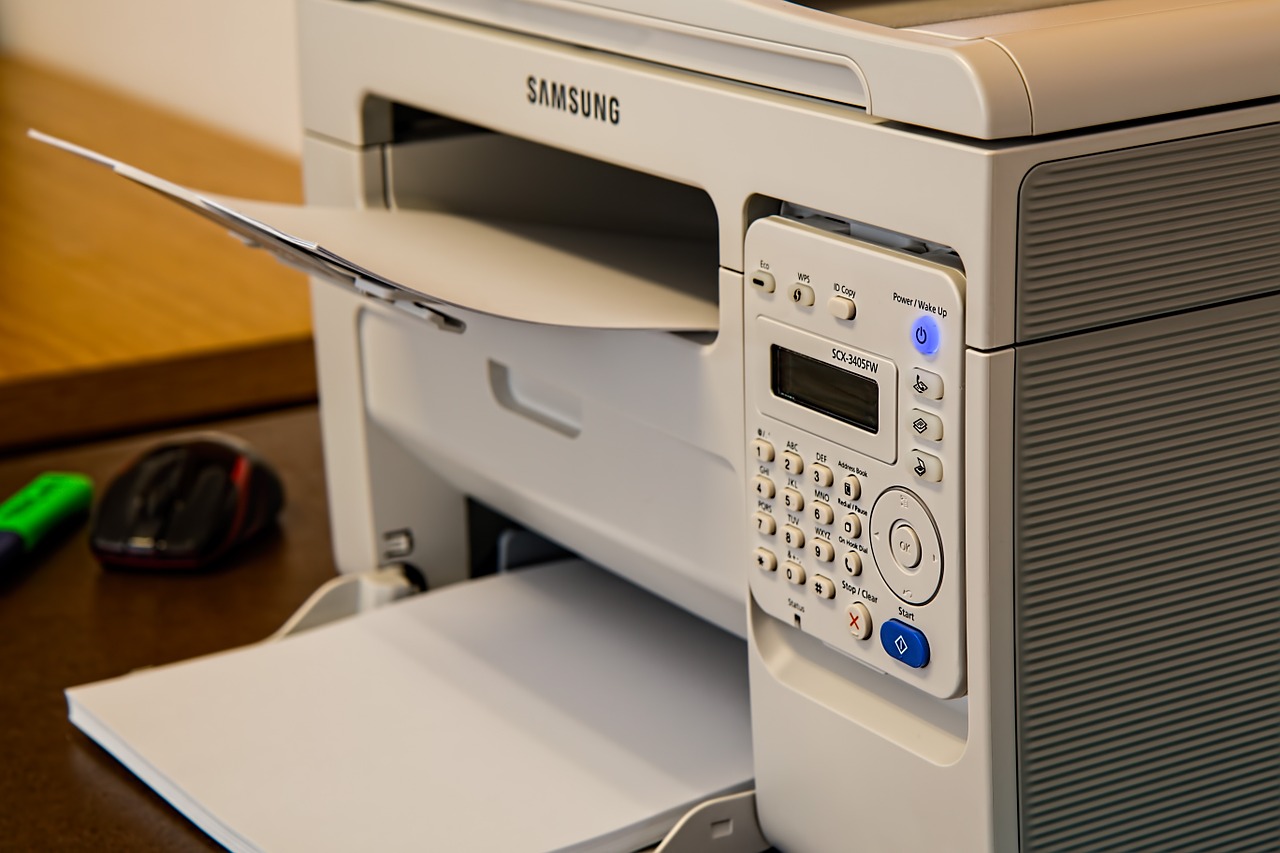

It All Started with a Printer

I was working on a distribution transformation in Japan that involved more than 12 operating companies across multiple sites. Billions of dollars of product were on the line. This was the equivalent of a brain transplant, a heart transplant, a full body switch; pick your favorite metaphor of “get this right.”

So usually, setting up physical infrastructure is seen as one of the simpler aspects of a project like this. It involves actual, readymade components being deployed to do well-understood things. It’s wonderfully boring and easy compared to doing a custom build out of software or facility.

But somewhere, buried among the thousands of tasks assigned to hundreds of people over several years, ordering printers for the pack-and-ship stations in the distribution center got flubbed.

We knew far in advance that we needed a lot of printers to complete the project. We figured there was no harm in ordering them early. In Japan, the earlier we could get the ball rolling, the better, since the “simple” act of ordering printers required nine signatures across departments, a dozen government offices to approve, and a byzantine network of shipping companies to deliver to site.

So we were proactive and planned to order the printers many months before go-live with plenty of buffer; smart, we thought, given that shipping these printers internationally would take at a minimum six weeks, more through customs, and more to get them to site, deployed, and tested.

We knew we should be safe if we had the printers with five months to spare, which would give us plenty of time to store, test, place, test, deploy, test (you can never test enough!) and start production. We even planned to buy 20% more than we needed just to be safe in case some didn’t pass testing (remember to test incessantly!).

By November, the Infrastructure Lead confirmed the status: “obtain confirmation of Label Printers procurement.”

Now, pay attention to this verbiage because it will come back to haunt us.

No one considered that beyond the leadership meeting to authorize this action and memorialization of that intent through a written memo ordering this man to procure the printers, that tracking procurement through its lifecycle was necessary until they arrived on the dock. After all, physical infrastructure was the easy, boring part of the project.

Fast forward to the day before Christmas. A random hallway conversation prompted the Project Director to ask who would go to the customs office to fill out paperwork for the arriving printers. An awkward and noncommittal response followed.

It turned out that the Infrastructure Lead hadn’t completed the procurement process! He hadn’t pushed the final “buy” button in the global procurement system because he wanted to first check out the storage location to ensure there was room for the extra printers. Naively assuming nothing could ever go wrong, he reasoned a little delay in placing the order would be harmless given the length of time to go-live.

Cue midnight phone calls and escalations. Fun with a capital F. We completed the procurement process that night but the damage had already been done.

What followed was an unreasonably comical series of unfortunate events.

The promised lead time by the printer supplier, of course, went from 6 to 18 weeks. The version of printers we needed, of course, suddenly wasn’t available so the ones we needed had to be imported from another country, which, of course, had no prior clearance through customs. This, naturally, would add another 24 weeks, which meant missed go-live and total failure.

Over the next three weeks, we scoured the global supply chain for like models of the printers to rapidly ship to Japan via any means necessary. Since what we could find was not a sound fit, separate software had to be procured from another supplier. A new team of printer integration developers had to be sourced and brought in to install the modules and make them compatible.

We finally received the printers 12 weeks before go-live; a bit tight, all things considered. Of course, during our first dress rehearsal, every 12th label came out blank. Huh.

Just so the situation is clear: these printers would ship hundreds of millions of dollars’ worth of products per week at very high daily volumes. A one-minute per-product delay would be material on the scale of senior executives going on an epic firing spree just before being fired themselves. These had to work perfectly – by Japanese standards – just so we are clear. So as things stood, mere weeks before go-live we couldn’t get the product out the door.

Dozens of people worked nights and weekends to figure out the issue. After auditing the entire code base and fully taking the printers apart and putting them back together, it was finally understood that it was the separately installed memory cartridges that weren’t sized appropriately to handle the Japanese character sets that required more memory as compared to the native English settings.

So at the 11th hour, the solution was finally discovered, and new commercial memory cartridges were bought locally and retrofitted into the printers by the project team. Another ad-hoc dress rehearsal, solely for the printers, was quickly set up, and—sigh of relief—they finally passed testing to actually be ready for production.

The Moral of the Story

The moral here is: you really need to get your status right. It’s the foundation of correct decision making. We had a status update, but as you recall, it was dangerously vague.

“Obtain confirmation of Label Printers procurement.”

Everyone assumed that the printers were ordered and shipped, however, one misguided misinterpretation of what “procurement” entailed resulted in the wrong signal, the wrong status, and the wrong understanding. The missing link was a status that provided positive confirmation that the right printers were ordered, shipped, and in-transit. Had the order been placed on time, the supplier would have had sufficient on-hand inventory, so the lead time would have remained at six weeks, the frankenstein assembly of other models would not have been necessary, and the memory module problem would thus not have occurred.

So who was responsible? Was it the Infrastructure Lead who went to check on the storage space? In part, but also: everyone.

It’s tempting to blame cultural differences, but most of us work in multinational environments, so we can’t lean too hard on that excuse.

This was an example of a confluence of misunderstandings and insufficient rigor for the absolute requirement of positive confirmation of the occurrence or non-occurrence of a specific outcome. And that boiled down to the simple fact that there was simply a lack of an appropriate status update. That “want of a status” caused a butterfly effect that very nearly destroyed the project.

And this is all too common: one small miscommunication in a status can cause a major snowball.

So what’s the solution? More frequent communication, for one. More frequent retrospectives on “completed” activities, another. Incessant vigilance is the only failsafe. Had that conversation not happened on Christmas Eve, the team might have been sitting on its hands, waiting for those ghost printers to show up. The tasks that relied on those printers arriving, being set up, and being tested would have then been delayed. The project would have gone way over budget and deadline.

So what is the moral here? Make sure you get your status, lest you lose your kingdom. A simple misstep in the wording of your status, or worse, an inaccurate status, can have a ripple effect that has far-reaching repercussions.

Share: